Amphenol CIT has extensive manufacturing facilities for Aero Structures of all shapes and sizes. Manufacturing facilities in Franklin Wisconsin and Coventry UK, have capabilities to work in a wide variety of aerospace metals including aluminum, stainless steel, titanium, and select composites. Sheet metal, 3- and 5-axis CNC, lathe, long bed machining, water jet, 3D printing, as well as in house finishing make turning your designs into high-quality pedigreed aircraft parts quick and easy. Manufacturing facilities are FAA PMA and EASA POA approved allowing parts to be delivered with airworthiness tags if requested. All parts receive AS9102 FAI and detailed inspection by an expert quality staff using the latest technology. Contact us today to discuss how Amphenol CIT can support your Aero Structures manufacturing from raw material all the way to flight-ready finished assembly.

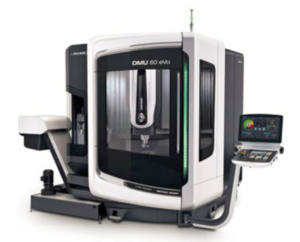

The DMU 60 eVo combines the flexibility of modern universal milling machines with the performance potential of vertical machining centers. The NC swivel rotary table offers 5-axis simultaneous machining for exceptional surface quality while also expanding your application possibilities with complete machining of single parts or in serial production runs.

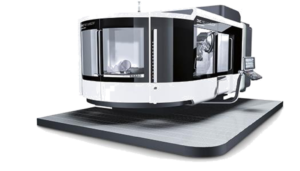

The DMG duoBLOCK 5-axis machines set the benchmark for maximum precision, performance and efficiency and are engineered specifically for cutting the challenging alloys used in aerospace.

Large parts demand large working platforms and maximum productivity. The DMC 160U offers a larger work platform without sacrificing any performance.

Due to its high-dynamic features, the ENDURA is particularly suitable for the high-efficiency machining of ruled geometries, cutting contours, pockets, surfaces, drill holes, threads and spindle operations. Offering the highest dynamics in its class, from roughing to high precision processing it achieves excellent surface results and dimensional accuracy.

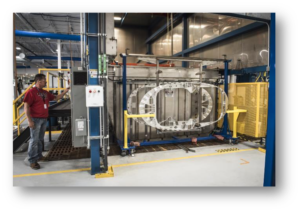

For parts much too big for lesser equipment, the CMS Poseidon offers a vast working area capable of handling long bed machining needs in aluminums or composites. Aircraft structural elements such as floor beams, frames, and stanchions are handled with ease using the dual 5-axis heads which can work in tandem or independently to maximize throughput.

The Z-2043 offers a high versatility water jet cutting solution which can accommodate sheets up to 12' in a wide variety of materials, including sheet metal, composites, foams, and more. This provides an attractive alternative to roughing operations using conventional machining centers and the ability to cut soft materials not suitable for conventional machining.

To inquire about Aero Structures available from Amphenol CIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields