Custom Capabilities Examples Shown from Left to Right: 2-Hole Narrow Tongue Terminal Lug; Bent Tongue; Splice; 1-Hole Tongue; Flag-Style Terminal Lug; Transition Splice

Looking for reliable solutions for critical components? Amphenol CIT sealed terminal lugs and splices are engineered not only to be reliable but also to reduce weight and provide efficient installation, driving down costs.

Our unique hex-crimp design allows for a crimp installation that produces no flash, saving costly operator time and minimizing damage to the protective plating. Whether your need is for a highly customized terminal lug or splice for a unique installation, or a standard product for rapid entry into service, Amphenol CIT provides the solution.

Amphenol CIT engineers connectors, installation tooling, and cable assembly systems that meet the most demanding of specifications.

Large Gauge Aluminum Splices from Amphenol CIT offers the fastest installation in the industry — a single crimp on each barrel that leaves no burrs for removal in secondary operations.

Amphenol CIT's sealed terminal lugs are engineered not only to be reliable but to also reduce weight and provide efficient installation, driving down costs

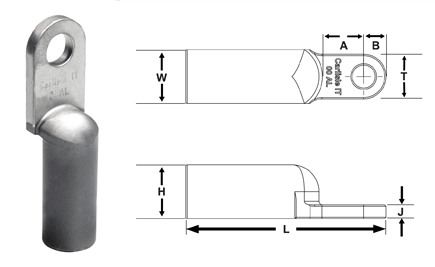

| Part No.* | Wire Size (AWG) | Stud Size | “L” mm (in) | “H” mm (in) | “W” mm (in) | “T” mm (in) | “J” mm (in) | “A” mm (in) | “B” mm (in) | Wire Strip Length mm (in) | Weight (grams) | Crimp Die Part No. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 695-18114-001** | 10 | 3/8” | 41.9 (1.65) | 8.0 (0.315) | 7.7 (0.305) | 14.8 (0.584) | 2.5 (0.098) | 12.1 (0.478) | 7.1 (0.280) | 13.5 ± 0.8 (0.530± 0.03) | 3.8 | 999-63002-100 |

| 695-18113-001** | 8 | 3/8” | 41.9 (1.65) | 8.8 (0.348) | 8.3 (0.328) | 14.8 (0.584) | 2.5 (0.098) | 11.7 (0.462) | 7.1 (0.280) | 13.5 ± 0.8 (0.530± 0.03) | 3.8 | 999-63003-100 |

| 695-18100-001 | 6 | 1/4” | 50.9 (2.00) | 10.4 (0.41) | 9.9 (0.39) | 16.4 (0.65) | 2.5 (0.10) | 15.0 (0.59) | 7.7 (0.30) | 15.1 ± 0.5 (0.59 ± 0.02) | 6.6 | 999-63004-200 |

| 695-18101-001 | 4 | 1/4” | 55.7 (2.19) | 12.8 (0.50) | 11.8 (0.46) | 15.8 (0.62) | 3.0 (0.12) | 15.0 (0.59) | 7.9 (0.31) | 15.9 ± 0.5 (0.63 ± 0.02) | 10.4 | 999-63005-500 |

| 695-18102-001 | 2 | 5/16” | 61.1 (2.41) | 15.5 (0.61) | 14.5 (0.57) | 16.8 (0.66) | 3.8 (0.15) | 15.0 (0.59) | 8.4 (0.33) | 19.7 ± 0.5 (0.76 ± 0.02) | 14.8 | 999-63006-200 |

| 695-18103-001 | 1/0 | 1/4” | 64.0 (2.52) | 18.7 (0.74) | 17.2 (0.68) | 16.0 (0.63) | 5.0 (0.20) | 15.0 (0.59) | 8.0 (0.31) | 20.8 ± 0.5 (0.82 ± 0.02) | 20 | 999-63007-200 |

| 695-18104-001 | 1/0 | 5/16” | 64.0 (2.52) | 18.7 (0.74) | 17.2 (0.68) | 16.2 (0.64) | 5.0 (0.20) | 15.0 (0.59) | 8.1 (0.32) | 20.8 ± 0.5 (0.82 ± 0.02) | 20 | 999-63007-200 |

| 695-18105-001 | 1/0 | 5/16” | 65.9 (2.59) | 18.2 (0.72) | 17.2 (0.68) | 20.0 (0.79) | 4.5 (0.18) | 15.0 (0.59) | 10.0 (0.39) | 20.8 ± 0.5 (0.82 ± 0.02) | 21.4 | 999-63007-200 |

| 695-18106-001 | 2/0 | 5/16” | 72.6 (2.86) | 19.6 (0.77) | 19.6 (0.77) | 16.2 (0.64) | 5.0 (0.20) | 15.0 (0.59) | 8.1 (0.32) | 25.5 ± 0.5 (1.00 ± 0.02) | 28.8 | 999-63008-200 |

| 695-18107-001 | 2/0 | 3/8” | 74.0 (2.91) | 20.5 (0.81) | 19.5 (0.77) | 19.0 (0.75) | 6.0 (0.24) | 15.0 (0.59) | 9.5 (0.37) | 25.5 ± 0.5 (1.00 ± 0.02) | 31 | 999-63008-200 |

* Append part number with “SN” for tin plating, “N” for nickel, and “N+” for enhanced nickel plating, e.g. for a tin-plated one-hole #10 AWG terminal lug, use part number 695-18114-001SN

** Part numbers 695-18114-001 and 695-18113-001 are governed by inch dimensions, not millimeters

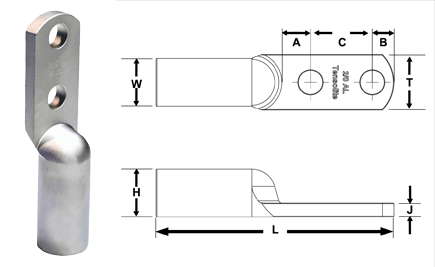

| Part No.* | Wire Size (AWG) | Stud Size | “L” In (mm) | “H” In (mm) | ”W” In (mm) | ”T” In (mm) | ”J” In (mm) | ”A” In (mm) | ”B” In (mm) | ”C” In (mm) | Wire Strip Length In (mm) | Weight (grams) | Crimp Die Part No. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 695-18114-002 | 10 | 3/8” | 2.61 (66.3) | 0.305 (7.75) | 0.305 (7.75) | 0.584 (14.83) | 0.098 (2.49) | 0.442 (11.23) | 0.280 (7.11) | 1.000 (25.40) | 0.52± 0.03 (13.2± 0.8) | 5.8 | 999-63002-100 |

| 695-18108-002 | 2 | 3/8” | 3.27 (83.1) | 0.573 (14.55) | 0.573 (14.55) | 0.670 (17.02) | 0.150 (3.81) | 0.44 (11.2) | 0.34 (8.6) | 1.000 (25.40) | 0.75 ± 0.02 (19.1 ± 0.5) | 16 | 999-63006-200 |

| 695-18109-002 | 1/0 | 3/8” | 3.39 (86.1) | 0.680 (17.27) | 0.680 (17.27) | 0.807 (20.50) | 0.180 (4.57) | 0.44 (11.2) | 0.35 (8.9) | 1.000 (25.40) | 0.80 ± 0.02 (20.3 ± 0.5) | 25.4 | 999-63007-200 |

| 695-18110-002 | 2/0 | 3/8” | 3.85 (97.8) | 0.775 (19.69) | 0.775 (19.69) | 0.900 (22.86) | 0.225 (5.72) | 0.46 (11.7) | 0.35 (8.9) | 1.000 (25.40) | 1.00 ± 0.03 (25.4 ± 0.5) | 38.5 | 999-63008-200 |

| 695-18111-002 | 3/0 | 3/8” | 3.86 (98.0) | 0.853 (21.67) | 0.853 (21.67) | 0.965 (24.51) | 0.250 (6.35) | 0.44 (11.2) | 0.35 (8.9) | 1.000 (25.40) | 0.99 ± 0.03 (25.1 ± 0.5) | 43.8 | 999-63012-100 |

| 695-18112-002 | 4/0 | 3/8” | 3.89 (98.8) | 0.942 (23.93) | 0.942 (23.93) | 0.985 (25.02) | 0.260 (6.60) | 0.44 (11.2) | 0.35 (8.9) | 1.000 (25.40) | 1.05 ± 0.03 (26.7 ± 0.5) | 52 | 999-63010-100 |

* Append part number with “SN” for tin plating, “N” for nickel, and “N+” for enhanced nickel plating, e.g. for a tin-plated, two-hole #10 AWG terminal lug, use part number 695-18114-002SN

Custom Terminal Lugs & Splices

Sealed Terminal Lugs & Tooling for Aluminum Cables

Crimp Die and Die Inspection Gauges

To inquire about Terminal Blocks, Lugs & Splices available from Amphenol CIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields