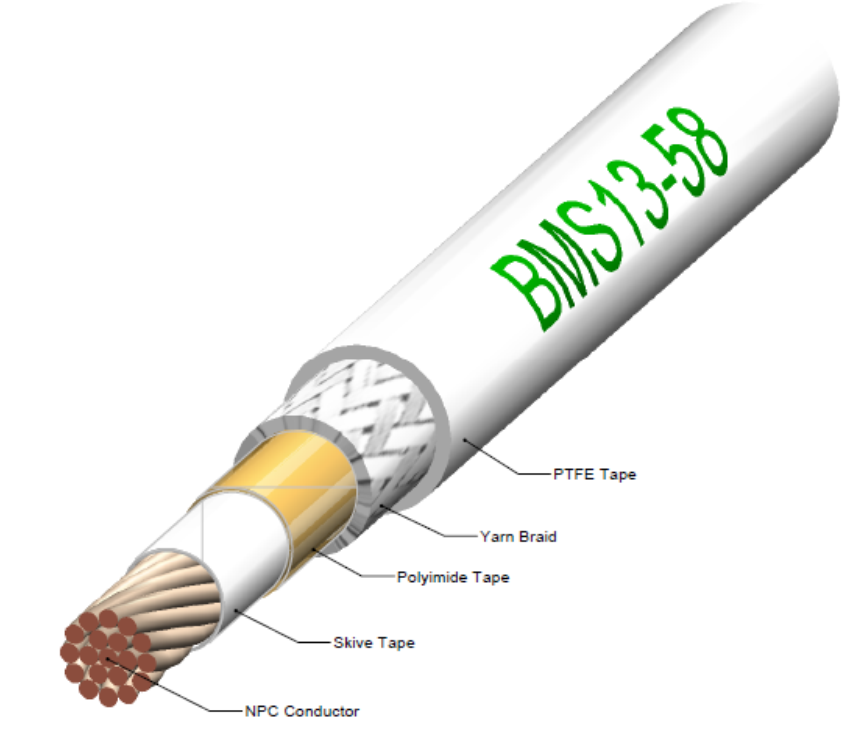

An image showing a BMS 13-58 wire with some coating removed to show the wire underneath.

SWAMP is the acronym for Severe Weather and Moisture Prone. Boeing Specification BMS 13-58 defines SWAMP wire construction.

BMS-13-58 cutaway

| Test | Requirements |

|---|---|

| Wire Rating | 260°C, 600V |

| Arc Resistance (Wet & Dry) | 67 wires must pass |

| Dynamic Cut Through | 50 lbs. min. |

| Wicking | 1/4" max. distance |

| Wire-to-Wire Abrasion | 7.5 million cycles |

| Wire Separation | Must pass dry dielectric after test |

| Wire Size (AWG) | Conductor Strands | Diameter of Stranded Conductor (in.) | Maximum DC Resistance (Ohms/1000 ft. at 20C Max) | ||||

| Number | AWG | Nominal Diameter (in) | Min. | Max. | Nickel Coated Copper | Nickel Coated | High Strength Copper |

|---|---|---|---|---|---|---|---|

| 24 | 19 | 36 | 0.0050 | 0.023 | 0.026 | 26.20 | 30.10 |

| 22 | 19 | 34 | 0.0063 | 0.029 | 0.033 | 16.00 | 18.60 |

| 20 | 19 | 32 | 0.0080 | 0.037 | 0.041 | 9.77 | 11.40 |

| 18 | 19 | 30 | 0.0100 | 0.046 | 0.051 | 6.70 | 7.20 |

| 16 | 19 | 29 | 0.0113 | 0.052 | 0.058 | 4.76 | 5.60 |

| 14 | 19 | 27 | 0.0142 | 0.065 | 0.073 | 3.00 | -- |

| 12 | 37 | 28 | 0.0126 | 0.084 | 0.090 | 1.98 | -- |

| 10 | 37 | 26 | 0.0159 | 0.106 | 0.114 | 1.24 | -- |

| 8 | 133 | 29 | 0.0113 | 0.158 | 0.173 | 0.694 | -- |

| 6 | 133 | 27 | 0.0142 | 0.198 | 0.217 | 0.436 | -- |

| 4 | 133 | 25 | 0.0179 | 0.250 | 0.274 | 0.275 | -- |

| 2 | 665 | 30 | 0.0100 | 0.320 | 0.340 | 0.177 | -- |

| 1/0 | 1045 | 30 | 0.0100 | 0.395 | 0.425 | 0.113 | -- |

| 2/0 | 1330 | 30 | 0.0100 | 0.440 | 0.475 | 0.089 | -- |

| 3/0 | 1665 | 30 | 0.0100 | 0.500 | 0.540 | 0.071 | -- |

| 4/0 | 2109 | 30 | 0.0100 | 0.565 | 0.605 | 0.056 | -- |

| TYPE | CLASS | WIRE SIZE (AWG) | INSULATION THICKNESS (MIL) | CONDUCTOR | SHIELD | JACKET | TEMPERATURE RATING (DEGREES C) | |||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| MIN | MAX | MIN | MAX | MATERIAL | COATING | MATERIAL | COATING | MATERIAL | MIN | MAX | ||

| 1 | 1 | 8 | 24 | 4/0 | 22 | Annealed Copper | Nickel | -- | -- | -- | -65 | 260 |

| 8 | ||||||||||||

| 12 | ||||||||||||

| 2 | 1 | 4 | 24 | 12 | 22 | Annealed Copper | Nickel | Copper Braid | Nickel | -- | -65 | 260 |

| 3 | 1 | 4 | 24 | 12 | 22 | Annealed Copper | Nickel | -- | -- | PTFE/Tape | -65 | 260 |

| 4 | 2 | 4 | 24 | 12 | 22 | Annealed Copper | Nickel | -- | -- | PTFE/Tape | -65 | 260 |

| 5 | 1 | 8 | 24 | 12 | 22 | High Strength Copper Alloy | Nickel | Copper Braid | Nickel | -- | -65 | 260 |

| 16 | ||||||||||||

| 6 | 1 | 4 | 24 | 16 | 22 | High Strength Copper Alloy | Nickel | Copper Braid | Nickel | -- | -65 | 260 |

| 7 | 1 | 4 | 24 | 16 | 22 | High Strength Copper Alloy | Nickel | Copper Braid | Nickel | PTFE/Tape | -65 | 260 |

| 8 | 2 | 4 | 24 | 16 | 22 | High Strength Copper Alloy | Nickel | -- | -- | PTFE/Tape | -65 | 260 |

| 9 | 1 | 3 | 24 | 18 | 22 | High Strength Copper Alloy | Nickel | Copper Braid | Nickel | PTFE/Tape | -65 | 260 |

To inquire about BMS 13-58 available from Amphenol CIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields