Amphenol CIT designs and manufactures a portfolio of wire and cable products designed for the Aerospace Engine market including harsh environment cable and wire. As the industry leader in high-temperature wire, Amphenol CIT's severe environment wires are designed to perform in extremely harsh environments, under vibration and with direct flame exposure.

Perfect for applications in engine compartments, fire detection circuits, flight critical systems and fly-by-wire systems where superior performance and temperature resistance are critical.

Amphenol CIT's General Purpose Engine Wire is designed for applications such as engine compartments, fire detection circuits, flight critical systems, and fly-by-wire systems where performance and temperature resistance is critical.

Amphenol CIT Seamless-T product line meets the enhanced "seamless" insulation and enhanced requirements of AS22759/180-/192, once again raising the bar for outstanding performance.

An increased wall thickness version utilizing an aluminum conductor for power feeder applications. Improved mechanical performance including superior flexibility as compared to traditional polyamide insulated power feeder cables. TLA is rated at 175°C.

This cable encompasses a family of wire and cable in three temperature ratings: 150°C, 200°C, and 260°C. ST is a multi-purpose normal weight wire which exhibits exceptional performance characteristics within the range of the critical parameters in airframe applications. This construction offers enhanced Hydrolysis Resistance and Cut-Through.

This cable encompasses a metric family of wire and cable with a temperature rating of 260°C. TLR is a multi-purpose normal weight wire which exhibits exceptional performance characteristics within the range of the critical parameters in airframe applications. 200°C and 260°C.

A thin wall, light weight version of ST which can be used in various constructions. It also has value when considered as a single conductor offering a 5% weight savings over the ST construction while maintaining the same mechanical properties. SLT is available in 150°C, 200ºC and 260ºC.

This cable encompasses a family of wire and cable in three temperature ratings: 150°C, 200°C, and 260°C. TL is a multi-purpose normal weight wire which exhibits exceptional performance characteristics within the range of the critical parameters in airframe applications.

An increased wall version which can be utilized in applications requiring superior mechanical capabilities such as abrasion resistance and dynamic cut-through. This insulation system may be used as a reduced size and weight replacement for MIL-W-22759/5 to /8. TLS is rated at 260°C.

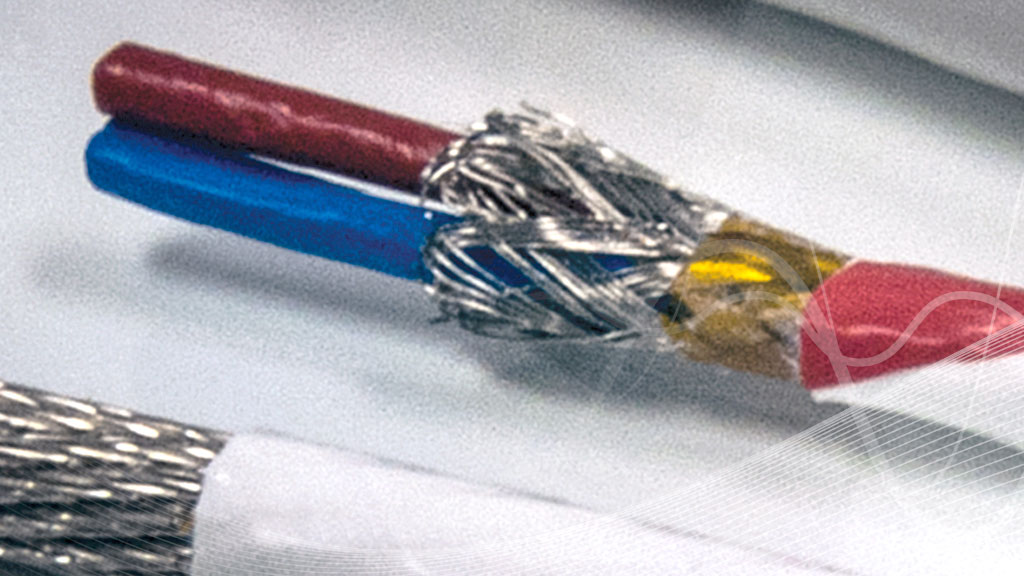

These wires are designed for critical circuit applications where wires must operate in extremely harsh environments, under vibration, and with direct flame exposure.

Amphenol CIT Thermazone™ Wire & Cable is designed to withstand aircraft engine fire-zones, operating continuously at 260°C, and for a minimum of 15 minutes of direct flame exposure up to 2000°F (1093°C).

Amphenol CIT’s Thermazone™ wires are designed for use in high temperature and severe environment applications such as engine wire, fire detection circuits, fly-by-wire systems and flight critical circuits.

A range of high temperature, fire proof and fire resistant single and multi-core cables, incorporating PTFE and Polyimide, specifically designed for use in fire zone areas of the aircraft engine.

BMS 13-55 is the Boeing specification for Firezone wire. These wires are designed for critical circuit applications where wires must operate in extremely harsh environments, under vibration, and with direct flame exposure.

These wires are designed for critical circuit applications where wires must operate in extremely harsh environments, under vibration, and with direct flame exposure.

Designed for Severe Weather and Moisture Prone (SWAMP) applications, such as wheel housings, wings and engine nacelles.

A composite insulation of glass and PTFE (Polytetrafluoroethylene), EFGLAS provides extreme strength, abrasion and temperature resistance from the combination of PTFE tape and a PTFE impregnated glass yarn braid.

SWAMP is the acronym for Severe Weather and Moisture Prone. Boeing Specification BMS 13-58 defines SWAMP wire construction.

To inquire about Harsh-Environment Engine Wire available from Amphenol CIT, please fill out the form below, and one of our Sales Engineers will contact you.

"*" indicates required fields